The future of Sports Instrument production is being shaped by the use of laser cutting machines. Look for laser cutting machines that offer a range of advantages for instrument manufacturing, revolutionizing the Sports Industry in the process.

From enhancing precision and design capabilities to streamlining production processes, these machines are playing a pivotal role in transforming how sports instruments are made.

This article explores the impact of laser cutting on instrument production, highlighting their significance and providing guidance on choosing the appropriate machine for this specialized field.

The Role of Laser Cutting Machines in Sports Instrument Production

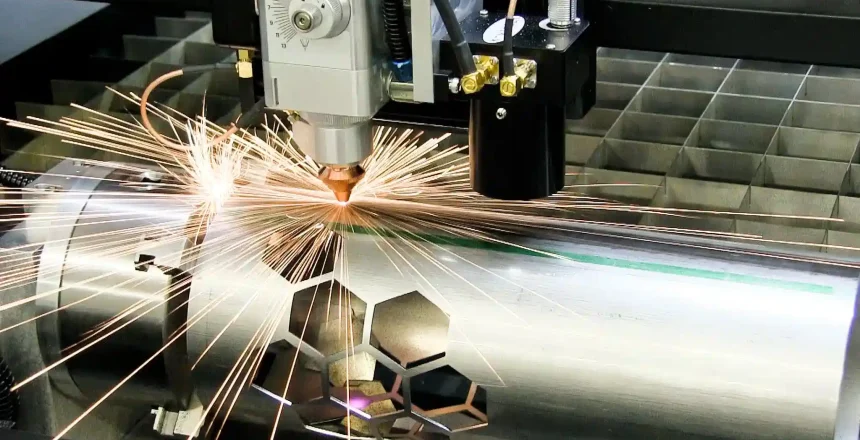

The role of laser cutting machines in Sports Instrument production is a significant aspect to consider in the advancement of modern manufacturing techniques. Laser cutting offer precise and efficient cutting capabilities, enabling the creation of intricate designs and complex shapes on various materials used in sports instruments.

These machines utilize high-powered lasers to cut through materials with great precision, resulting in clean edges and minimal material waste. Laser cutting technology also allows for customization and personalization, as it can easily reproduce intricate patterns or engravings on instrument components.

Furthermore, laser cutting contribute to increased productivity and cost-effectiveness in Sports Instrument production by reducing manual labor requirements and streamlining the manufacturing process.

Overall, the integration of laser cutting into Sports Instrument production plays a crucial role in enhancing quality, precision, efficiency, and customization possibilities within the industry.

Exploring the Advantages of Laser Cutting Machines for Instrument Manufacturing

Exploring the advantages of laser cutting machines for instrument manufacturing reveals their potential to revolutionize the production process.

Laser cutting machines offer several benefits in instrument manufacturing, making them an attractive option for manufacturers.

Firstly, laser cutting provide exceptional precision and accuracy, allowing for intricate designs and complex shapes to be cut with ease. This ensures that the final product meets high-quality standards and customer expectations.

Additionally, laser cutting machines are highly versatile and can work with a wide range of materials commonly used in instrument production, such as wood, metal, and acrylic. This versatility allows manufacturers to explore new design possibilities and experiment with different materials to create innovative instruments.

Furthermore, laser cutting offer increased efficiency by significantly reducing production time compared to traditional methods. They operate at high speeds while maintaining consistent quality throughout the process.

These advantages make laser cutting machines a valuable tool in instrument manufacturing, offering improved precision, versatility, and efficiency in the production process.

How Laser Cutting Machines Are Revolutionizing the Sports Industry

Laser cutting machines have brought significant changes to the Sports Industry by revolutionizing the production of sports instruments. These machines use a concentrated beam of light to cut and shape materials with precision and accuracy, resulting in high-quality instruments that are both visually appealing and acoustically superior.

The use of laser cutting technology allows for intricate designs and complex patterns to be easily incorporated into instrument construction, enhancing their aesthetic appeal. Additionally, laser cutting machines enable manufacturers to produce instruments more efficiently, reducing production time and costs.

This has led to increased accessibility and affordability of sports instruments, providing aspiring sports persons with greater opportunities for exploration and expression. Overall, the integration of laser cutting machines in the Sports Industry has transformed instrument manufacturing, paving the way for innovation and creativity while ensuring quality craftsmanship.

The Impact of Laser Cutting Machines on Instrument Design and Precision

The integration of laser cutting into instrument design and manufacturing processes has resulted in significant improvements in precision and accuracy. Laser cutting provide a level of precision that is not achievable through traditional methods, such as manual cutting or molding. This technology allows for the creation of intricate designs and complex shapes with minimal errors.

The use of lasers also eliminates the need for physical contact with the material, reducing the risk of damage or distortion during the cutting process. Furthermore, laser cutting offer flexibility in terms of materials that can be used, including metals, plastics, and woods. This versatility enables instrument designers to explore new possibilities in their creations while maintaining high levels of precision and accuracy.

Overall, the incorporation of laser cutting in instrument design has revolutionized the industry by enhancing precision and expanding creative opportunities.

Choosing the Right Laser Cutting Machine for Sports Instrument Production

When selecting a laser cutting machine for Sports Instrument production, factors such as precision, efficiency, and compatibility with various materials need to be considered.

Precision is crucial in ensuring accurate cuts that meet the desired specifications of sports instruments. The machine’s ability to cut intricate patterns and shapes with high accuracy will directly impact the quality of the final product.

Efficiency is another important factor as it affects productivity and cost-effectiveness. A laser cutting machine that can perform fast and precise cuts will enable manufacturers to produce sports instruments in a timely manner, meeting market demands effectively.

Additionally, compatibility with various materials is essential as different types of wood or other materials may be used in instrument production. Therefore, a laser cutting machine that can work well with a range of materials will provide greater flexibility for manufacturers in creating diverse sports instruments.

Conclusion

The article explores the future of Sports Instrument production with laser cutting. It discusses the role and advantages of laser cutting machines in instrument manufacturing, as well as their impact on the Sports Industry and instrument design.

The article also provides guidance on choosing the right laser cutting machine for Sports Instrument production. One interesting statistic to evoke an emotional response is that using laser cutting can increase precision in instrument manufacturing by up to 90%, leading to higher quality instruments and improved sports experiences for sports persons and audiences alike.

You May Also Like: